BILSTEIN Advanced High Strength Low Alloy (AHSLA)

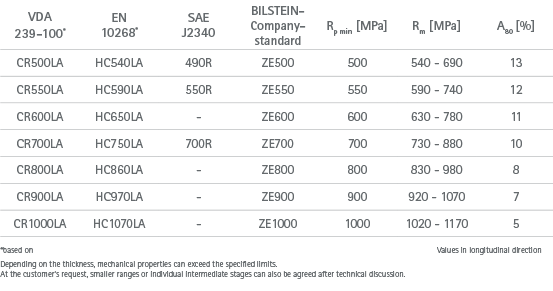

Notation, standards and mechanical properties

The chemical composition of these grades corresponds to the standard of DIN EN 10268. In addition to a worldwide material availability those grades provide excellent weldability with all common processes due to the low C-equivalent.

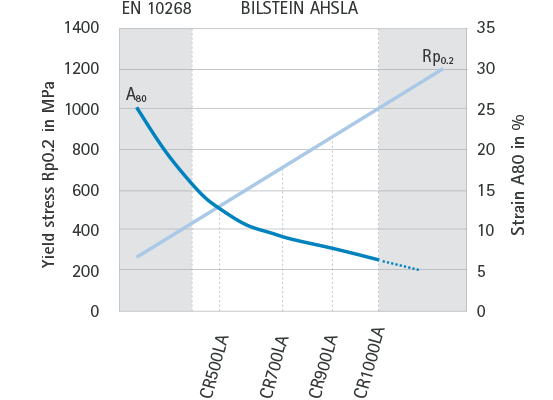

Due to the single-phase microstructure outstanding homogeneous material properties can be achieved with positive effects, for example with regard to the beneficial hole expansion ratios. Furthermore, high yield-to-tensile ratios of >95% also offer best conditions for cold forming processes like of roll forming.

BILSTEIN AHSLA are available over a wide thickness range up to a width of 1350 mm. Typically, the grades are supplied with thickness and width tolerances in accordance with DIN EN 10140 and surfaces in accordance with DIN EN 10139. In addition to individual customer requirements for surfaces or tolerances, application-related individual mechanical properties, that deviate from the standard, can also be agreed.

To protect the surfaces, metallic coatings can be applied electrolytically to the coils. Alternatively,

highly corrosion-resistant zincflake coatings as well as wet and powder coatings can be applied to the component or final product.

Due to the mentioned properties these high-strength materials are already meeting the high requirements of the automotive industry for years now. Currently they are used, for example, in seating structures, airbag systems or transmission transmission

components.

BILSTEIN AHSLA will continue to demonstrate its advantages in the future with regard to lightweight applications in electromobility as well as the availability of CO2-reduced variants.

BILSTEIN Advanced High Strength Low Alloy (AHSLA)

Application area

- seat rails

- safety belt housings

- Clutch disks

- …

| Thickness* | 0.25 mm (0.0197 inch) – 5.0 mm (0.197 inch) |

|---|---|

| Width* | Mill edge: up to 1.350 mm (53.15 inch)

Cut edge: 15 mm (0.59 inch) up to 1.320 mm (51.97 inch) |

| Delivery format | coil |

| Coil weight | max. 23 kg/mm of width → max. 2 lbs/inch of width |

*Grade and cross section depending